- Mob.:+86 186 1359 2768

+86 182 3593 6828 - E-mail: service1@sxltsj.com

sales3@sxltsj.com

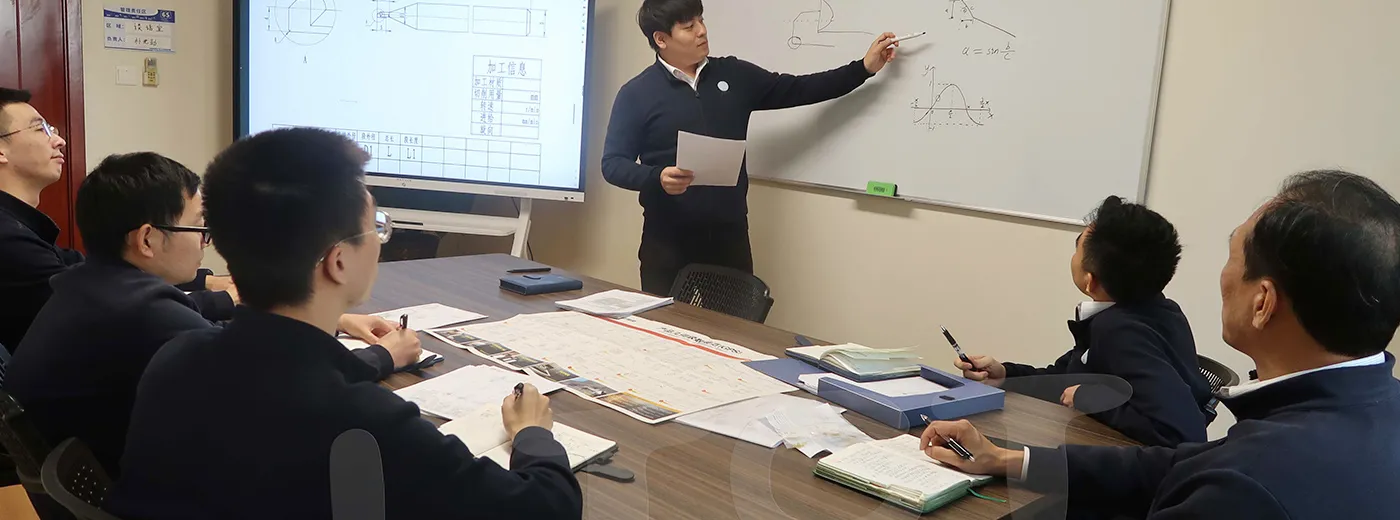

With over 30 years of experience in the diamond industry, our R&D staff knows diamonds very well. Using advanced processing equipment and testing instruments abroad, we cooperate with well-known domestic universities and scientific research institutions. The rich knowledge and team allow us to continuously work on tools development and solutions.

A Dust-free workshop is our main base for research and development. In this workshop our research and development staff conduct simulation studies and tests, which can provide better solutions.

Since its establishment, Litian Century has been committed to providing customers with high quality products.

Our company has set up an independent Quality Control Center, with trained professional quality inspection personnel and advanced equipment. A strict quality inspection process has been developed, from the selection of raw materials, semi-finished products and finished products inspection have strict standards and requirements, in line with the ISO management system certification.